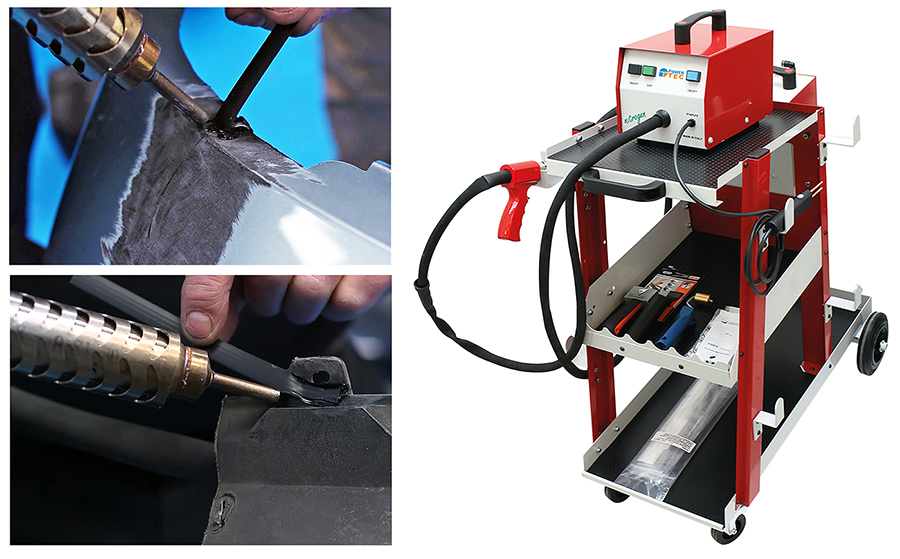

92452 Nitrogen Plastic Welder with Generator

Plastic welder with its own nitrogen generator, that eliminates the need for a nitrogen gas bottle. Workshop compressed air is used to maintain consistent temperature between welds. Makes repairs that are stronger than any two-part epoxy or hot air weld. The plastics are melted together, with no oxidation, to form the strongest possible weld.

- Compatible with almost every plastic type used in the automotive industry.

- Has its own nitrogen generator which eliminates the need for a gas bottle.

- Allows the welding of filler material by heating with nitrogen.

- The welder comes complete with a set of plastic consumables including a scraper & roller to finalise the repair.

- Heats plastic without combustion & therefore without emitting fumes: 230v, 50Hz, 1600w, 20-650°C. Made in Italy.

List Price: £4882.48 ex VAT £5858.98 inc VAT

Plastic welder with its own nitrogen generator, that eliminates the need for a nitrogen gas bottle. Workshop compressed air is used to maintain consistent temperature between welds. Makes repairs that are stronger than any two-part epoxy or hot air weld. The plastics are melted together, with no oxidation, to form the strongest possible weld.

- Kompatibel mit nahezu allen in der Automobilindustrie verwendeten Kunststofftypen

- Mit eigenem Stickstoffgenerator, so dass eine Gasflasche überflüssig wird

- Gestattet das Schweißen von Zusatzwerkstoff durch Erhitzen mit Stickstoff-Kunststoffschweißgerät

- Das Schweißgerät wird komplett mit einem Satz Kunststoff-Verbrauchsmaterial, einem Abschaber und einer Rolle zum Abschließen der Reparatur geliefert.

- Erhitzt Kunststoff ohne Verbrennung und damit ohne Austritt von Abgasen 230 V, 50 Hz, 1600 W, 20 bis 650 °C, Made in Italy

List Price: £4882.48 ex VAT £5858.98 inc VAT

Useful Downloads

Related Products

Press Release

The strongest plastic welding — with the Nitrogen plastic welder from Power-TEC

Plastic welding with nitrogen gas creates the strongest welds possible because it eliminates oxidisation of the plastic during the welding process. The new nitrogen plastic welding system from Power-TEC (part number 92452) includes everything needed to become immediately productive making strong and very quick plastic repairs on virtually any type of plastic.

And there is no concern of ever running out of nitrogen, as the Power-TEC 92452 features an inbuilt nitrogen generator that eliminates the need for a nitrogen gas bottle. Workshop Compressed air is used to maintain consistent temperature between welds — the nitrogen is only activated when pulling the trigger so that it’s not wasted between welds.

Identify the plastic material, choose the compatible plastic filler and the compact, easy-to-handle welding torch gets right into tight spots, making stronger welds than with any other method. A hot stapler is used to stabilise and secure the area during the repair process, plus both a brass roller and a metal scraper that are used to smooth off and reduce any excess material. The result is a strong, plastic-only repair that can then be finished and repainted.

Particularly useful for repairing mounting tabs and flanges, which can be difficult to repair successfully using other methods, plus with nitrogen welding there is no material build-up. The repaired tab is as strong and flexible as it was before the damage. If welding from behind, the nitrogen welding process keeps the heat localised, with no damage to the painted outer surface.

Versatile, quick, cost-saving and easy — the nitrogen-generating plastic welder from Power-TEC.